Aluminium Frame

Aluminium frames refer to structures or frameworks constructed using aluminum as the primary material. These frames are versatile and find applications in various industries and products.

Construction and Design:

➤Material:Aluminium frames are constructed using aluminum alloy, which is lightweight, durable, and corrosion-resistant.

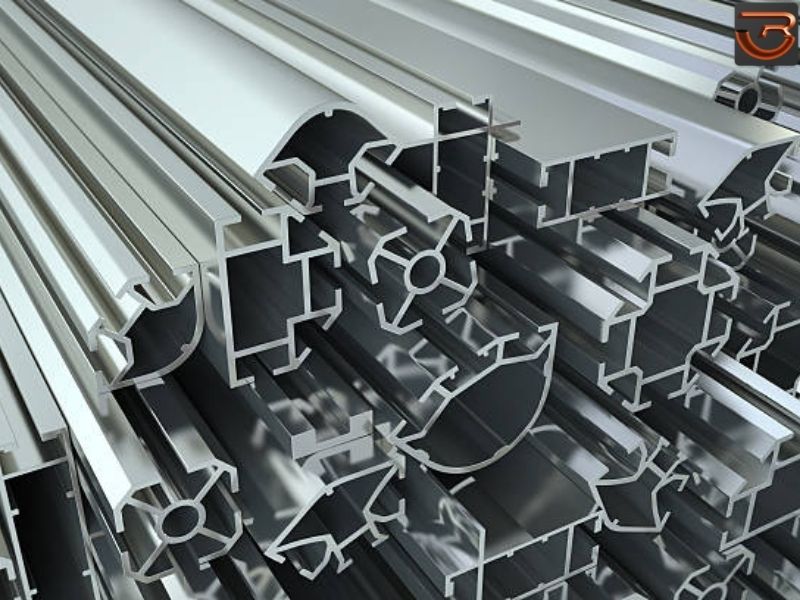

➤Profile Design:Aluminium frames come in various profile designs, offering flexibility in shape and size.

➤Finishes:The frames can have different finishes, such as anodized, powder-coated, or painted, providing aesthetic options and enhancing durability.

Advantages of Aluminium Frames:

➤Lightweight:Aluminium is significantly lighter than steel, making frames easy to handle and install.

➤Strength and Durability:Despite its lightweight nature, aluminium is strong and durable, providing stability and longevity to frames.

➤Corrosion Resistance:Aluminium naturally forms a protective oxide layer, making frames resistant to corrosion and suitable for outdoor use.

➤Versatility:Aluminium frames are versatile and can be used in various applications, from windows and doors to industrial structures.

➤Recyclability:Aluminium is highly recyclable, contributing to sustainable and eco-friendly practices.

Applications of Aluminium Frames:

➤Windows and Doors:Aluminium frames are commonly used in the construction of windows and doors. They provide a sleek and modern appearance while offering strength and durability.

➤Industrial Structures:In industrial settings, aluminium frames may be used for constructing structures like warehouses, factories, and assembly lines.

➤Automotive Industry:Aluminium frames are utilized in the automotive industry for constructing vehicle chassis and frames, contributing to weight reduction and fuel efficiency.

➤Solar Panels:Frames for solar panels are often made of aluminium due to its lightweight nature and resistance to corrosion.

➤Furniture:Aluminium frames are used in the construction of various types of furniture, including tables, chairs, and shelving units.

➤Bicycles:Lightweight and durable, aluminium frames are popular in the construction of bicycles.

➤Picture Frames:Aluminium is a common material for picture frames due to its sleek appearance and versatility.

Fabrication Techniques:

➤Extrusion:Aluminium frames are often created through extrusion, a process where the metal is forced through a die to create a specific shape.

➤Welding:Welding is commonly used to join aluminium frame components, ensuring structural integrity.

Aluminium Frames

| Alloy: Aluminium frames are typically made from various alloys, with popular choices being 6061 and 6063. These alloys offer a good balance of strength, durability, and workability. |

| Temper: The temper of the aluminum frames refers to the heat treatment it undergoes. Common tempers include T5 and T6, each offering different levels of strength and hardness. |

| Thickness: Aluminium frames come in different thicknesses, catering to various applications. Common thicknesses range from 1.0mm to 3.0mm, depending on the structural requirements. |

| Width: The width of aluminum frames can vary widely based on the intended use. It could range from narrow profiles for lightweight applications to broader frames for heavy-duty structures. |

| Pattern: The pattern on the aluminum frames can add aesthetic value. Some frames may have a smooth finish, while others might feature patterns or textures for design purposes. |

| Standard: Compliance with industry standards ensures quality and performance. Common standards include ASTM (American Society for Testing and Materials) and EN (European Norms). |

| Surface Treatment: Aluminium frames may undergo surface treatments like anodizing or powder coating for enhanced corrosion resistance, improved aesthetics, and increased durability. |

| PVC Coated: Some aluminum frames come with PVC coating for additional protection against environmental elements and to provide a more finished appearance. |

| MOQ (Minimum Order Quantity): Manufacturers often specify a minimum quantity that customers must order. This helps streamline production processes and maintain cost efficiency. |

| Packing: Details about how the aluminum frames are packed for shipping, ensuring they reach the customer in optimal condition. This could include information on packaging materials and methods. |

| Port of Dispatch: Specifies the port from which the goods will be sent. This is crucial for logistics and shipping arrangements. |

| Delivery Time: The estimated time it takes for the aluminum frames to be delivered from the time of order placement. Factors such as production time, shipping, and customs clearance contribute to the overall delivery time. |

| Payment: Information on accepted payment methods and terms. This could include details on advance payments, letter of credit, or other financial arrangements. TT / LC / TT+LC |

Maintenance:

➤Low Maintenance:Aluminium frames are low-maintenance and can be easily cleaned with mild detergents and water.

Customization Options:

➤Color Options:Powder coating allows for a variety of color options, enabling customization to match or complement the aesthetic of the surrounding environment.

Energy Efficiency:

➤Thermal Breaks:Aluminium frames can be designed with thermal breaks or insulated profiles to enhance energy efficiency in windows and doors.