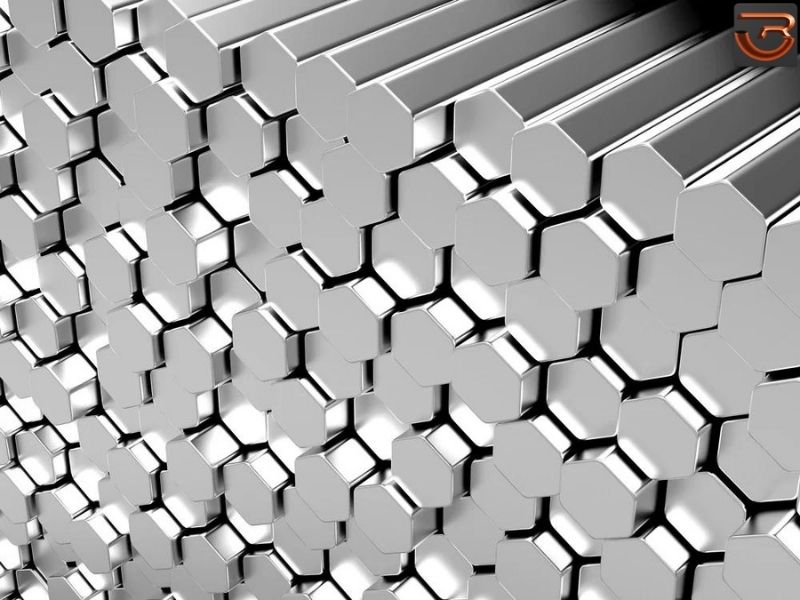

Aluminum alloy 3105 is primarily used in sheet and plate forms due to its good corrosion resistance and formability. Finding hexagonal bars in this alloy might be less common.

| Details and Characteristics: |

|---|

|

Corrosion Resistance: 3105 exhibits good corrosion resistance, making it suitable for applications where corrosion is a concern. It is often used in environments where exposure to moisture and certain chemicals is expected. Formability: It offers good formability, allowing for various forming and fabrication processes. Weldability: 3105 aluminum is easily weldable using various welding methods, including MIG and TIG welding. It is suitable for both manual and machine welding processes. Applications: Siding materials Heat exchangers Beverage can ends Cooking utensils Chemical equipment Surface Finish: The surface finish of 3105 aluminum hex bars can vary based on manufacturing processes. It can be finished to achieve different levels of smoothness or roughness. |

Alloy : 3105 Aluminium Alloy

Temper:

O H14 H18 / T351 T3 T4 / H24 H26 H16 / H32 H111 H321 H116 H112 / T6 T651 / T7451 T6511

Diameter: 10mm-500mm

Length: 500mm-6000mm

Standard: GB/T 3880-2012 ASTMB209 EN485

Surface Treatment: Mill Finish / Brush PSolish / Bright Finish

MOQ: The inventory has no MOQ 2mt-3mt

Packing: Standard Export Packing

Port of Dispatch: It depends on the supplier's location and shipping arrangements

Delivery Time: The inventory is 5-7 days . 25-30 days for customized products

Payment: TT / LC / TT+LC

Chemical Composition |

|

| Aluminum (Al): | 99.0% |

|---|---|

| Copper (Cu): | 0.30% |

| Iron (Fe): | 0.7% |

| Manganese (Mn): | 0.3% |

| Magnesium (Mg): | 0.20-0.8% |

| Zinc (Zn): | 0.40% |

| Chromium (Cr): | 0.20% |

| Other elements: | 0.05% each, 0.15% total |

Phone:

Mobile:

Email: