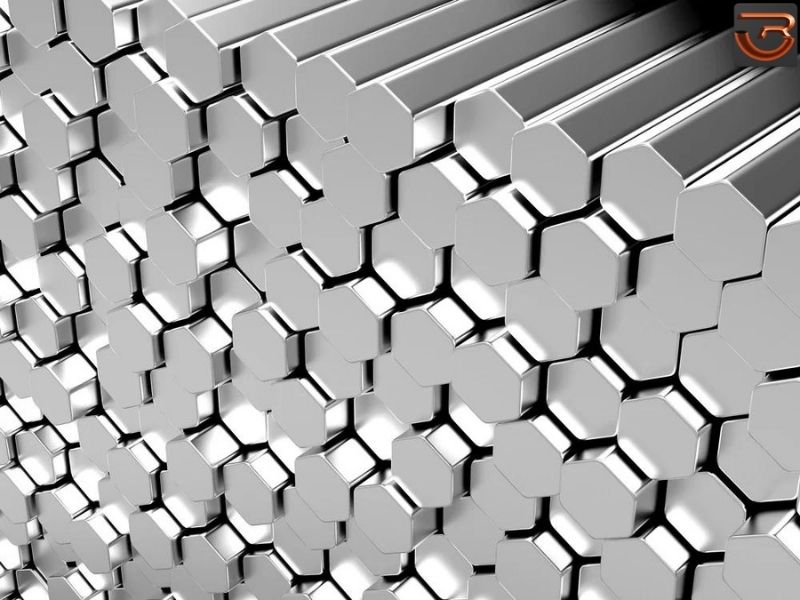

5754 Aluminium Hex Bar

Aluminum alloy 5754 is known for its excellent corrosion resistance, weldability, and high strength. However, hexagonal bars specifically made from alloy 5754 might be less common.

| Details and Characteristics: |

|---|

|

Corrosion Resistance: 5754 exhibits excellent corrosion resistance, particularly in marine environments. It is commonly used for shipbuilding and other maritime applications. Weldability: 5754 aluminum is highly weldable using various welding methods, including MIG and TIG welding. It is commonly used in welded structures where both strength and corrosion resistance are essential. High Strength: This alloy offers good strength and is often used in structural applications where both corrosion resistance and strength are important. Applications: Shipbuilding and marine components Automotive components, such as body panels Welded structures requiring corrosion resistance Pressure vessels Architectural applications Surface Finish: The surface finish of 5754 aluminum hex bars, if available, can vary based on manufacturing processes. It can be finished to achieve different levels of smoothness or roughness. |

5754 Aluminium Hex Bars

Alloy : 5754 Aluminium Alloy

Temper:

O H14 H18 / T351 T3 T4 / H24 H26 H16 / H32 H111 H321 H116 H112 / T6 T651 / T7451 T6511

Diameter: 10mm-500mm

Length: 500mm-6000mm

Standard: GB/T 3880-2012 ASTMB209 EN485

Surface Treatment: Mill Finish / Brush PSolish / Bright Finish

MOQ: The inventory has no MOQ 2mt-3mt

Packing: Standard Export Packing

Port of Dispatch: It depends on the supplier's location and shipping arrangements

Delivery Time: The inventory is 5-7 days . 25-30 days for customized products

Payment: TT / LC / TT+LC

Chemical Composition |

|

| Aluminum (Al): | 94.7% |

|---|---|

| Magnesium (Mg): | 2.6-3.6% |

| Manganese (Mn): | 0.50% |

| Iron (Fe): | 0.40% |

| Silicon (Si): | 0.30% |

| Copper (Cu): | 0.10% |

| Zinc (Zn): | 0.20% |

| Chromium (Cr): | 0.15% |

| Other elements: | 0.05% each, 0.15% total |