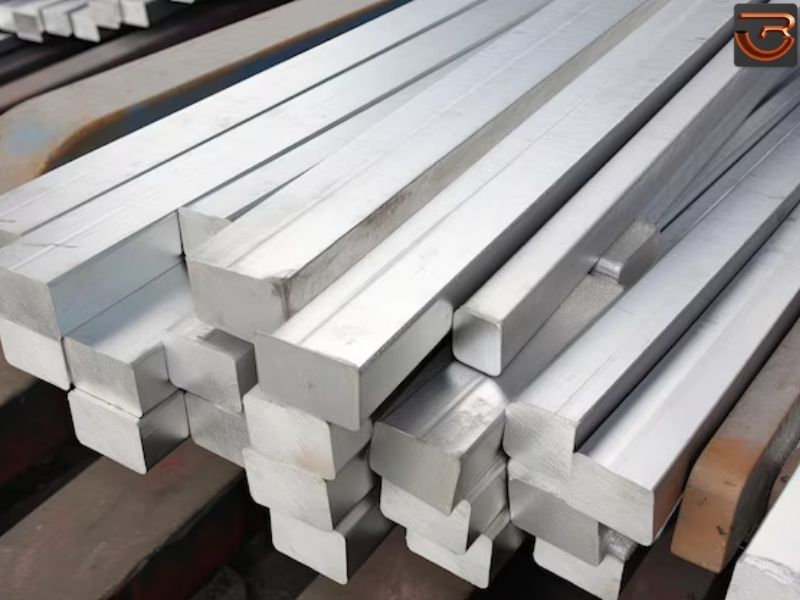

7075 aluminium flat bars can vary based on the manufacturer and customer requirements. Using 7075 aluminium for a specific application, it's advisable to consult with the relevant standards and specifications to ensure the alloy's suitability for the intended use.

| Details and Characteristics: |

|---|

Good Machinability: This alloy has good machinability, although it can be more challenging to machine compared to some other aluminium alloys. Heat Treatment: 7075 aluminium is heat-treatable and can be strengthened through various heat treatment processes, such as solution heat treatment and artificial aging. Surface Finish: The surface finish of 7075 aluminium flat bar can vary based on manufacturing processes. It can be finished to achieve different levels of smoothness or roughness. High Strength: 7075 is one of the highest strength aluminium alloys, known for its excellent strength-to-weight ratio. It is often used in applications where strength is a critical factor. Corrosion Resistance: 7075 aluminium has good corrosion resistance, although it is not as corrosion-resistant as some other aluminium alloys. It is often used in aerospace and high-stress applications. |

Alloy : 7075 Aluminium Alloy

Temper:

O H14 H18 / T351 T3 T4 / H24 H26 H16 / H32 H111 H321 H116 H112 / T6 T651 / T7451 T6511

Diameter: 10mm-500mm

Length: 500mm-6000mm

Standard: GB/T 3880-2012 ASTMB209 EN485

Surface Treatment: Mill Finish / Brush PSolish / Bright Finish

MOQ: The inventory has no MOQ 2mt-3mt

Packing: Standard Export Packing

Port of Dispatch: It depends on the supplier's location and shipping arrangements

Delivery Time: The inventory is 5-7 days . 25-30 days for customized products

Payment: TT / LC / TT+LC

Chemical Composition |

|

| Aluminium (Al): | 87.1% |

|---|---|

| Zinc (Zn): | 5.1-6.1% |

| Copper (Cu): | 1.2-2.0% |

| Magnesium (Mg): | 2.1-2.9% |

| Chromium (Cr): | 0.18-0.28% |

| Manganese (Mn): | 1.0% |

| Iron (Fe): | 0.50% |

| Silicon (Si): | 0.40% |

| Titanium (Ti): | 0.20% |

| Other | 0.05%(each) 0.15(total) |

Phone:

Mobile:

Email: