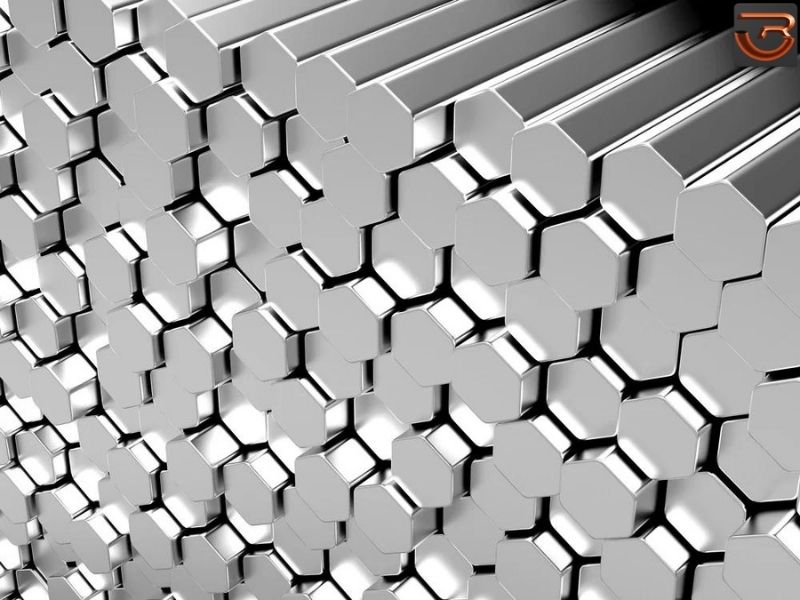

Aluminium alloy 7075 is a high-strength alloy known for its excellent strength-to-weight ratio and good corrosion resistance.

| Details and Characteristics: |

|---|

Corrosion Resistance: 7075 exhibits good corrosion resistance, particularly in aerospace and high-strength applications. It is not as corrosion-resistant as some other aluminum alloys like 6061 in certain environments. Weldability: 7075 is generally considered more challenging to weld compared to other aluminum alloys due to its high strength. However, it can be welded using certain techniques, and specific welding processes may be required. Applications: Aerospace components, Aircraft structures and Fuselage components | High-strength structural applications | Sports equipment, such as bicycle frames | Military and defense industry applications | Automotive components requiring high strength |

Alloy : 7075 Aluminium Alloy

Temper:

O H14 H18 / T351 T3 T4 / H24 H26 H16 / H32 H111 H321 H116 H112 / T6 T651 / T7451 T6511

Diameter: 10mm-500mm

Length: 500mm-6000mm

Standard: GB/T 3880-2012 ASTMB209 EN485

Surface Treatment: Mill Finish / Brush PSolish / Bright Finish

MOQ: The inventory has no MOQ 2mt-3mt

Packing: Standard Export Packing

Port of Dispatch: It depends on the supplier's location and shipping arrangements

Delivery Time: The inventory is 5-7 days . 25-30 days for customized products

Payment: TT / LC / TT+LC

Chemical Composition |

|

| Aluminium (Al): | 90.7% |

|---|---|

| Zinc (Zn): | 5.6% |

| Copper (Cu): | 2.5% |

| Magnesium (Mg): | 1.6% |

| Chromium (Cr): | 0.23% |

| Manganese (Mn): | 0.30% |

| Other elements: | 0.05% each, 0.15% total |

Phone:

Mobile:

Email: